Calibrating nuts

Profit from our know-how in nut processing and increase your productivity in all processes.

Calibrating nuts according to size.

Divide the walnuts into various size classes.

The calibration of the nuts is a decisive step for the further processing of the walnuts. The walnuts must be sorted into various sizes in order to achieve a very good drying and cracking result. For larger quantities, automatic calibration machines are used.

These machines work with calibration drums with holes of different sizes. Using the rotating calibration sieves, the walnuts are then calibrated in size classes.

Machines for calibrating nuts from Feucht Obsttechnik

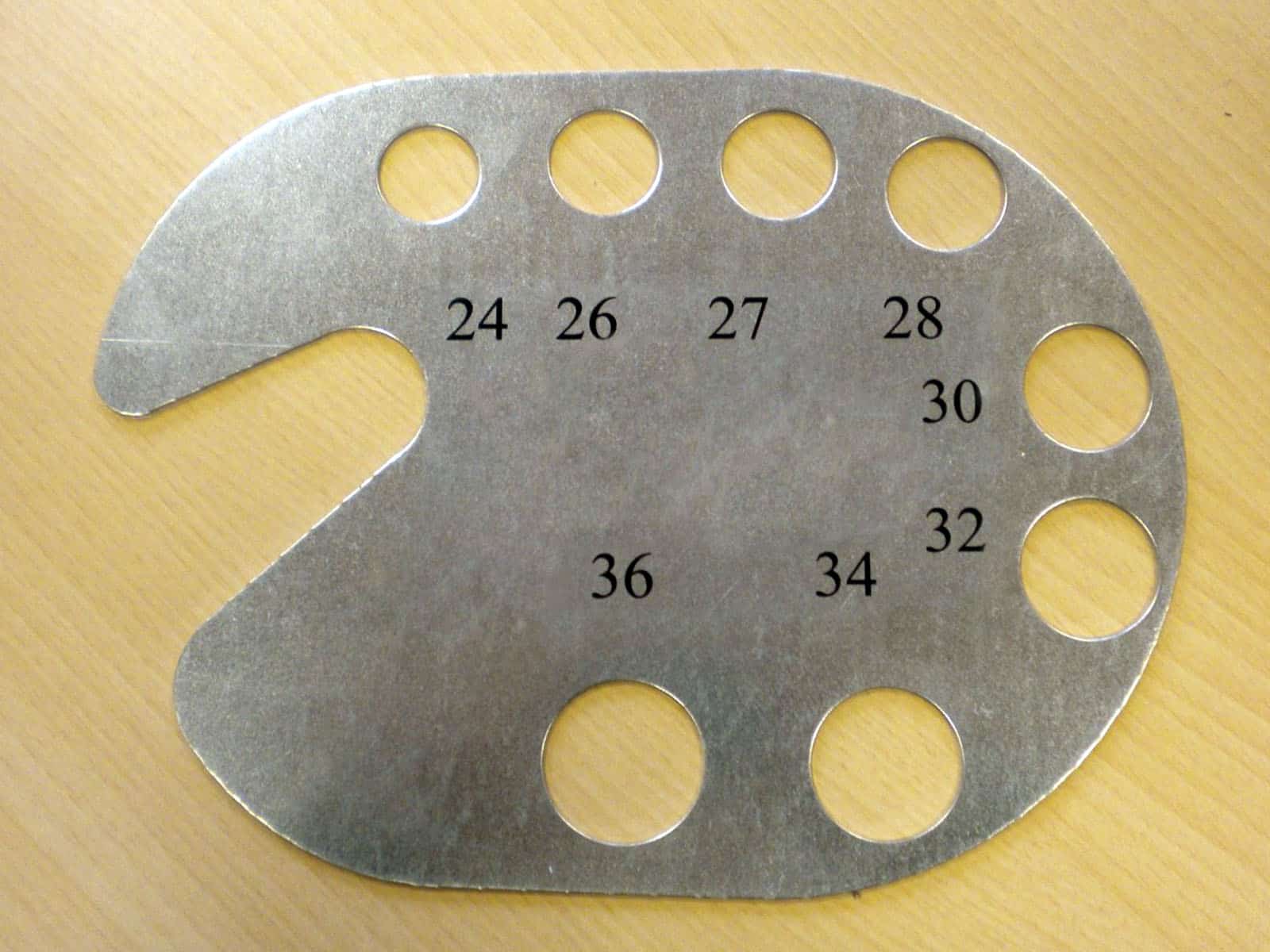

Hand stencil

Using the hand stencil, a size can be selected to determine the calibration sieve.

The calibration of the nuts is a decisive step for the further processing of the walnuts. The walnuts must be sorted into various sizes in order to achieve a very good drying and cracking result. For larger quantities, automatic calibration machines are used.

These machines work with calibration drums with holes of different sizes. Using the rotating calibration sieves, the walnuts are then calibrated in size classes.

Details on the hand stencil

Benefits

- exact determination of the nut size for mechanical calibration

- comprehensive calibration sizes

- other calibration sizes possible

Technical data

|

Length:

|

25 cm |

|

Width:

|

19 cm |

|

Thickness:

|

0.2 cm |

|

Weight:

|

0.366 kg |

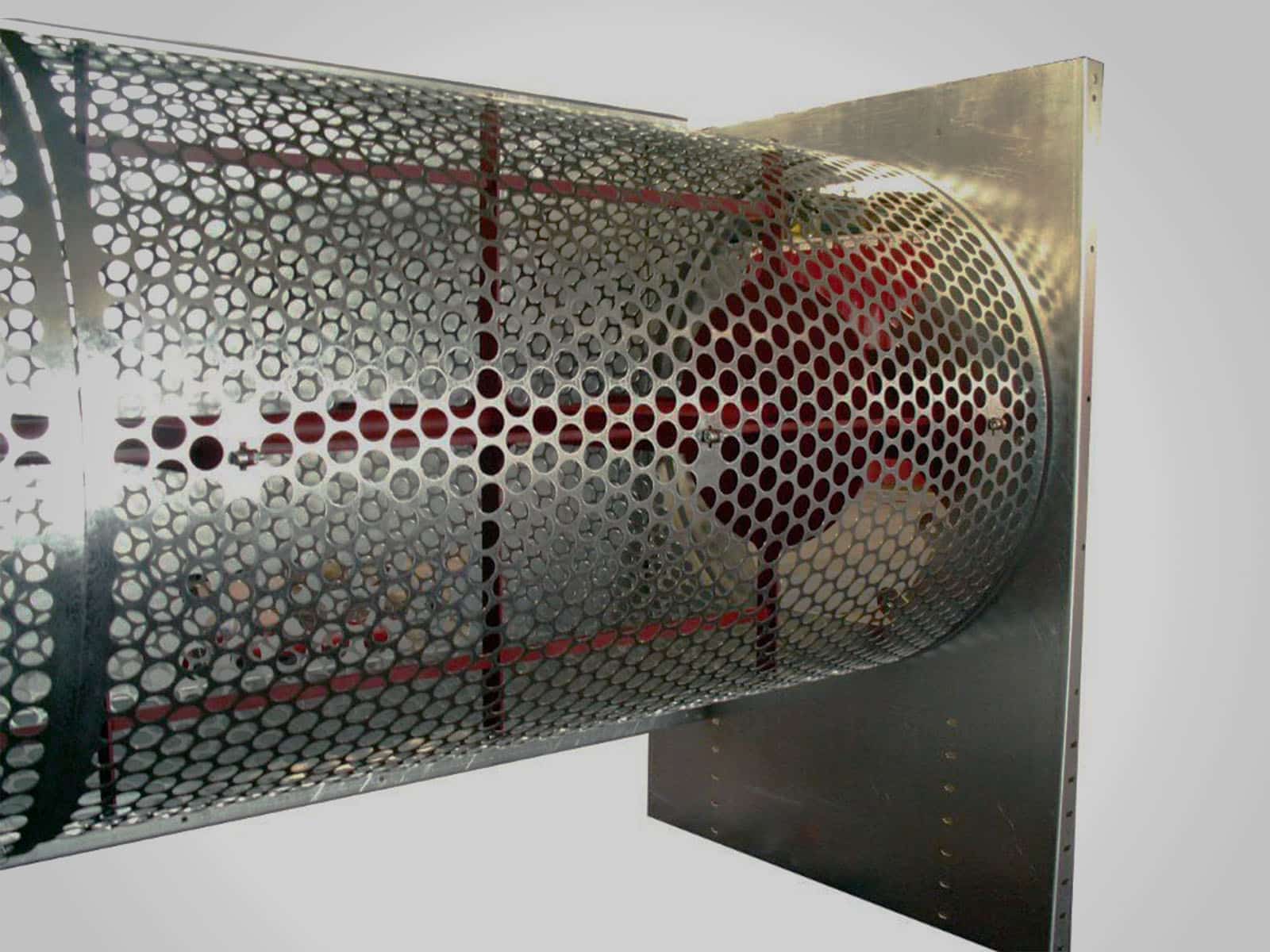

Cylindrical nut calibration machine

Calibrate from 100 kg to 1,000 kg nuts per hour.

The nut calibration machine has a calibration drum. This can sort the nuts in the same operation according to the same or 2 different sizes (optionally also up to 4 sizes). In addition, the sorting sieve can be changed easily and quickly.

Calibration sieves are available for every diameter. The working and total height are variably adjustable. The drive of the cylindrical calibration machine is via a worm gear or with an elastic coupling. Using an optional plastic sieve, chestnuts can also be gently calibrated.

Details zur Nusskalibriermaschine

Technical data

|

Types:

|

C10 (1m) | C10 (2m) | C25 | C37 |

|---|---|---|---|---|

|

Length:

|

250 cm | 290 cm | 300 cm | 440 cm |

|

Width:

|

87 cm | 87 cm | 87.5 cm | 87.5 cm |

|

Height:

|

90 – 170 cm | 90 – 170 cm | 200 cm | 120 cm |

|

Drum length:

|

100 cm | 200 cm | 2250 cm | 375 cm |

|

Drum diameter:

|

63.5 cm | 63.5 cm | 78.5 cm |

approx. 100 cm

|

|

Weight:

|

119 kg | 182 kg | 365 kg | 640 kg |

|

Flow rate:

|

120 kg/h |

350 kg/h (one calibration)

350 kg/h (one calibration) 250 kg/h (two calibrations) |

1000 kg/h (one calibration)

300 kg/h (two calibrations) |

1125 kg/h (one calibration)

1000 kg/h (two calibrations) |

| Motor: |

0.18 kW worm gear / 380 V

|

0.18 kW worm gear / 380 V

|

Worm geared drive motor / 380 V

|

0.55 kW worm geared drive motor / 380 V

|

|

Suitable for nut diameter:

|

1.0 – 3.6 cm (selection by the customer)

|

|||

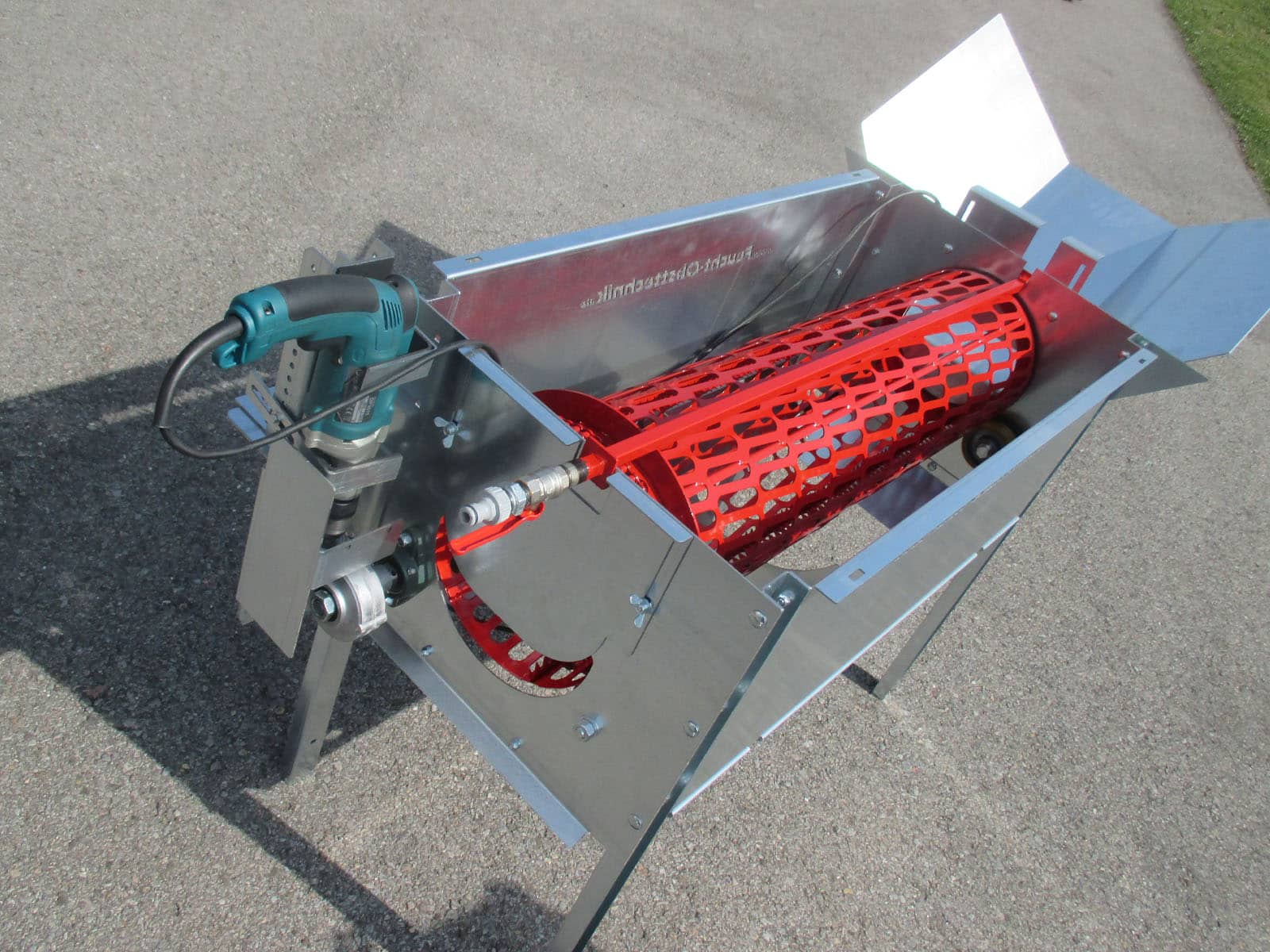

Washing and calibration machine

The universal machine for cleaning, calibration, and dividing walnuts.

The washing and calibration machine cleans and sorts the nuts according to size. Thus, up to 95% of the raw shells are separated from the nuts. For the cleaning, a wash drum (oval design) is used. The roller / drum is then exchanged with a round hole sieve for calibrating the nuts.

You can choose between two calibration values. It is driven by a standard drill. Optional with feeding of the nuts or electric motor with 230V.

Details on the washing and calibration machine

Benefits

- multi-function combination device for washing, calibrating, and dividing

- easy transport due to light weight

- various calibration sizes possible

- special calibration sizes possible upon request

- Optional: Feeding the nuts or electric motor with 230V

Technical data

|

Length:

|

160 cm |

|

Width:

|

65 cm |

|

Height:

|

105 cm |

|

Weight:

|

65 kg |

|

Performance:

|

Washing – approx. 100– 120 kg/h (20kg/drum every 10 minutes)

Calibrating – approx. 150 kg/h (in two sizes) |

|

Scope of delivery:

|

1x washing and calibration machine

|

|

1x wash drum

|

|

|

1x calibration sieve (diameter – 28/30)

|

|

| 1x calibration sieve (diameter – 30/32) | |

|

Other sieve sizes are available upon request, e.g. 14/16 or 18/20

|

|

|

The drill is not included in the scope of delivery

|