Drying nuts

Profit from our know-how in nut processing and increase your productivity in all processes.

Drying nuts carefully and quickly.

Preserve nuts using drying storage or heating devices.

After washing, the nuts must be quickly dried. Drying not only ensures a high quality of the precious nut cores by preventing mould, but also a long shelf life of the nuts. The fresh nuts are dried in a warm, dry air stream with temperature between 20° and 36°C up to a residual moisture of approx. 5 – 12%. The temperature control however depends on the size and the degree of moisture of the nut.

The drying process can be carried out with nut storage or special heating devices for nut drying.

Machines for drying nuts from Feucht Obsttechnik

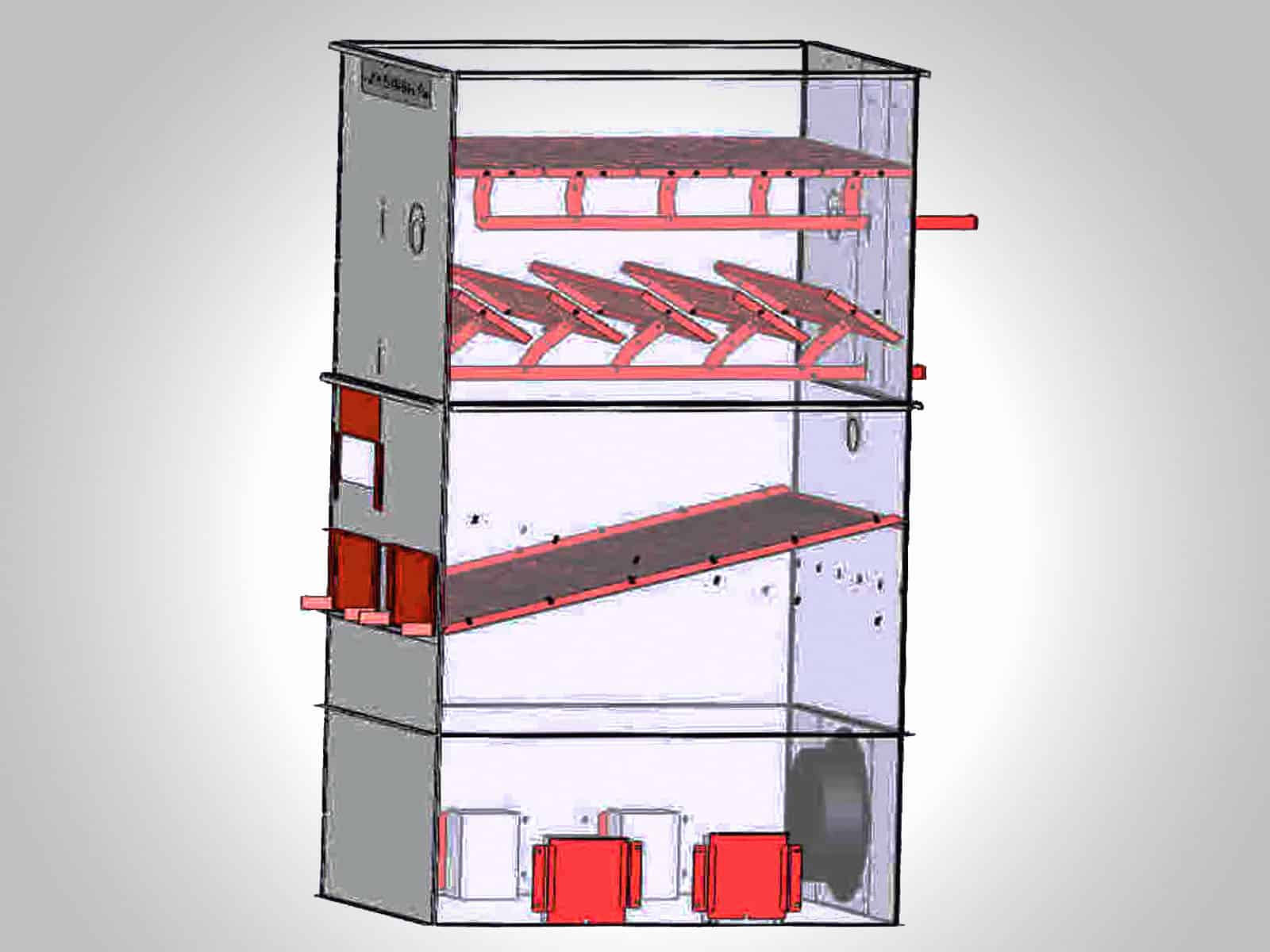

Multi-level drying storage

Drying nuts efficiently and economically.

The multi-level drying storage system allows the nuts to dry uniformly by constant movement. The walnuts are pre-dried in the upper levels and finish drying in the lower levels. This allows for a higher air temperature (30° to 36°C).

The nuts are transported from top to bottom by gravity. The drying capacity can be expanded through the addition of sections. The multi-level drying storage for nuts is equipped with several hinged doors and a central opening. In addition, the drying storage is available with helicoidal or centrifugal heating with different heating capacities according to the size of the storage. The degree of moisture of the nuts can be checked with the optionally available moisture meter.

Details on the multi-level drying storage

Benefits

- the drying sections are galvanised and screwed (supplied in building kit for self-assembly)

- size of the drying storage is expandable through the addition of sections (up to 4 levels)

- centrifugal or helicoidal heating with different heating capacities, dependent on the size of the drying storage

- this system is the most economical because of the air stream and the high heating capacity

- uniform drying through constant movement of the nuts

- the walnuts are pre-dried in the upper levels and finish drying in the lower levels

- high drying temperature from 30° to 36°C

Technical data

|

Length:

|

200 cm or 250 cm |

|

Width:

|

200 cm or 250 cm |

|

Height:

|

325 cm – 575 cm (dependent on the number of levels) |

|

Weight:

|

Dependent on the number of levels (2 – 4 levels)

|

|

Scope of delivery:

|

Building kit for self-assembly

|

| Optional: | Moisture meter for checking the degree of moisture of the nut |

Maxi dryer

The drying storage for large amounts.

Thanks to the Maxi Dryer, large quantities of nuts can be dried in a short time and with very good quality. Up to 1,000 litres of dried nuts can be produced approximately every 24 hours. During the drying process, the nuts are stored on 3 different height levels.

The lower level is the outlet used to empty the dry nuts. Then, both of the upper stages are opened so that the nuts fall down one level. The upper level can be filled with fresh nuts. The air stream is generated with a gas heater and a blower on the rear of the drying storage. The moisture of the nut can be checked using our additionally available

moisture meter.

Details zum Trockner Maxi

Benefits

- uniform drying through various levels

- thermostat for automatic switching of the gas heater

- temperature control

- uniform ventilation

- large capacity

- powerful propane gas heater

Technical data

|

Length:

|

120 cm |

|

Width:

|

120 cm |

|

Height:

|

272 cm |

|

Weight:

|

200 kg |

|

Performance:

|

15 – 30 kW with propane gas heater |

|

Capacity:

|

2,100 l |

|

Flow rate:

|

Up to 1000 l/24h

|

|

Scope of delivery:

|

1x dryer as building kit

1x propane gas heater

|

| Optional: | Nut moisture meter |

Mini dryer

The gentle drying storage with expandable capacity.

With the Mini dryer, up to 40 litres of nuts can be dried. For this, an adjustable fan heater generates a warm, uniform air stream (36°). The fan heater is directly connected to the drying storage. A flap allows the moisture of the nuts to be monitored throughout the process. This means that the Mini Dryer can be used to achieve an excellent drying result.

The dry nuts are then emptied through a large outlet. The Mini Dryer has 2 stages. The capacity of the drying storage can be increased with an expansion (contains 2 levels).

Details on the Mini dryer

Benefits

- adjustable temperature

- constant moisture monitoring possible

- up to 40 litres of dried nuts every 24 hours

- expandable drying capacity (additional 80 l/24 h expandable with attachment)

- simple operation

- very easy transport due to low weight

Technical data

|

Mini dryer

|

Expansion for Mini dryer

|

|

|

Length:

|

45 cm | 45 cm |

|

Width:

|

48 cm | 48 cm |

|

Height:

|

110 cm | 70 cm |

|

Weight:

|

28.5 kg | 20 kg |

|

Performance:

|

1kW / 2.5 kW | 1kW / 2.5 kW |

|

Capacity:

|

1x 40 l/24h | 2x 40 l/24h |

|

Flow rate:

|

40 l/24h | 80 l/24h |

|

Scope of delivery:

|

1x dryer as building kit

1x fan heater

1x box 40 l

|

Delivery as building kit

|

Heating devices for nut drying from Feucht Obsttechnik

Heating devices for nut drying from Feucht Obsttechnik

Drying nuts with the centrifugal hot air generator.

The centrifuge is a powerful hot air generator for nut processing. With this heating device nuts can be dried in a certain time at a certain moisture level.

We offer a large selection of centrifugal drying devices with various heating capacities, adjusted to the volumes of the drying storage. The moisture of the nut can be constantly monitored using our additionally optional moisture meter

Details on the centrifugal dryer

Benefits

- Various heating capacities selectable, dependent on the size of the drying storage

- including a digital thermometer

- contains 2 thermostats: safety thermostat and regulatory thermostat

- powerful due to propane gas heating

Technical data

|

Types:

|

5,5 Cv | 7,5 Cv | 10 Cv | 15 Cv |

|---|---|---|---|---|

|

Length:

|

155 cm | 155 cm | 155 cm | 125 cm 110 cm |

|

Width:

|

80 cm | 91 cm | 91 cm | 110 cm |

|

Height:

|

117 cm | 132 cm | 132 cm | 149 cm |

|

Motor:

|

4 kW | 5,5 kW | 7,5 kW | 11 kW |

|

Heating capacity:

|

100 – 200 kW | |||

| Optional: | Moisture meter for nuts | |||

Helicoil blower with gas heating

Drying nuts with the Helicoil hot air generator.

Indirectly fired air heaters such as the Helicoil blower are optimal solutions for the provision of clean and dry amounts of air for the heating of drying storage.

The Helicoil dryer has a carriage that allows easy relocation and versatile use. The Helicoil blower is available with different heating capacities according to the scope of the drying storage. In order to monitor the optimal moisture of the nuts, a moisture meter can be used.

Details on the Helicoil dryer

Benefits

- including temperature regulator

- overheating protection for very good safety conditions

- various heating capacities selectable according to the size of the drying storage

- carriage facilitates versatile use

- operated with propane gas

Technical data

| Motor: | kW 3.00 – 4.00 – 5.50 – 7.50 |

|

Length:

|

160 cm |

|

Width:

|

100 cm (including carriage) |

|

Heating capacity:

|

80 – 150 kW |

|

Diameter:

|

80 cm |

| Optional: | Moisture meter for nuts |