Cracking nuts

Profit from our know-how in nut processing and increase your productivity in all processes.

Professionally separate the nut core from the shell.

Crack nuts with cracking machines, post-cracking machines, and shell removers.

Cracking the nuts is the final process step in nut processing. The nuts are gently cracked using efficient walnut cracking machines. Depending on the size of the harvest, different sized cracking machines can be used.

For the best results, additional post-cracking machines can be used. In addition, blowers or shell removers are used to separate the precious nut core from the cracked shell. This achieves an excellent cracking result and minimises rework.

Machines for cracking nuts from Feucht Obsttechnik

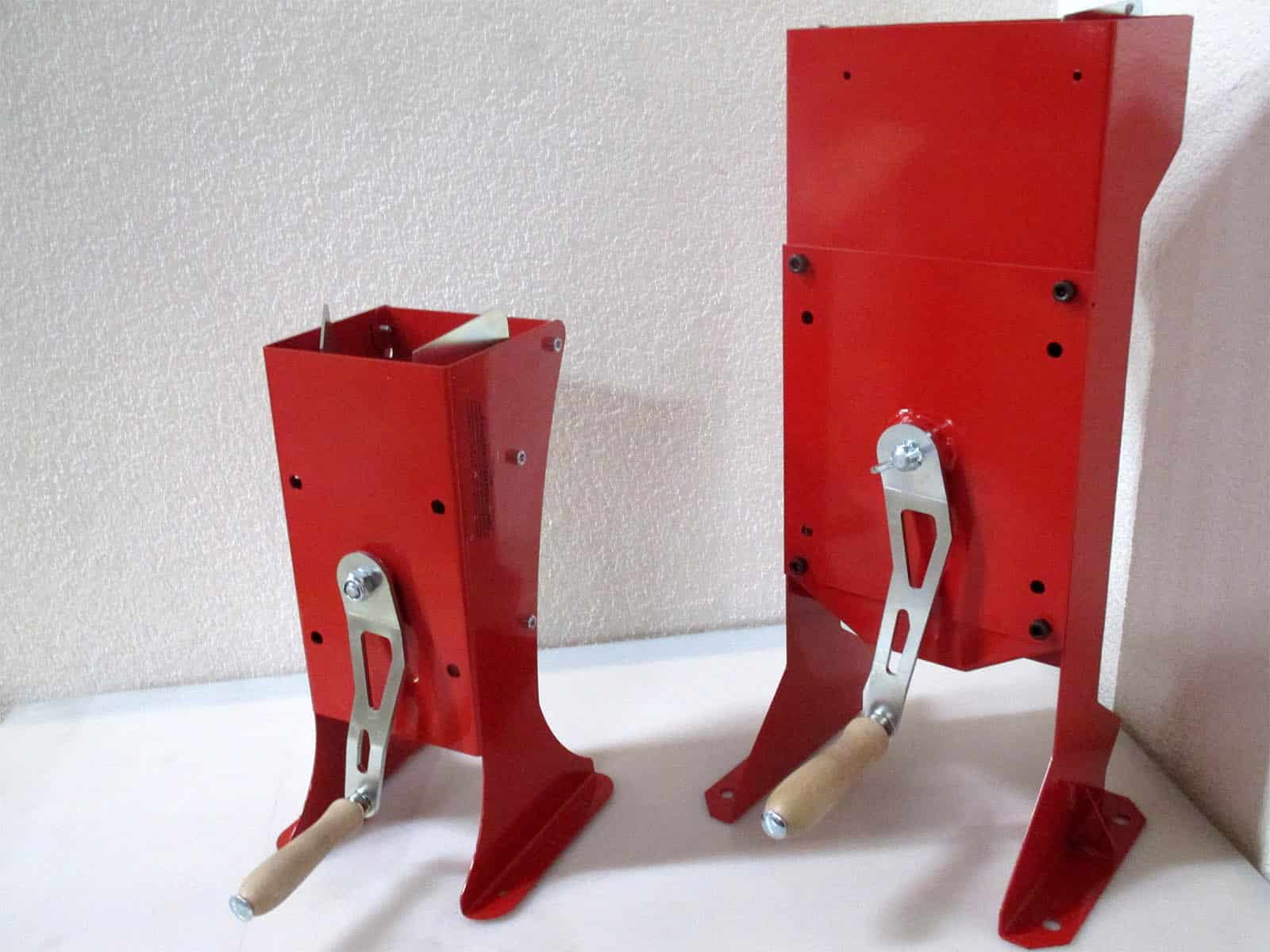

WAL MAN hand cracker and accessories

The WAL MAN and WAL MAN small are automatic, hand-operated nut crackers. Depending on the design, either up to 15 kg/h or up to 30 kg/h can be cracked. The nut cracker is very easy to use and is impressive due to its robust construction. Made in Germany. The cracking result is very clean with up to 40 % half cores for top quality walnuts and about 70 – 80 % whole cores for walnuts.

The WAL MAN is also optionally available with mechanical drive (electric motor) or shell remover with blower.

Details on the hand cracker and accessory

Nut cracker Micro

Process up to 30 kg nuts per hour with the economical nut cracking machine.

The Nut cracker Micro is especially suitable for smaller nut productions. The nut cracking machine cracks one nut at a time. For an optimal cracking result, the nuts must be washed and dried. A calibration is not absolutely necessary, but is recommended for the best cracking result. Thanks to its low weight, the Nut cracker Micro can be transported easily.

It is equipped with a 230V single-phase motor and a stone safety device. The Nut cracker Micro can optionally be combined with the Blower 400 for shell removal.

Details on the Nut cracker Micro

Benefits

- easy loading

- no supervision of the cracking process necessary

- safe working with stone safety device

- 38 l capacity

- cracking even without calibration possible

- simple transport thanks to light weight

- combinable with Blower 400 for shell removal

Technical data

|

Length:

|

84 cm |

|

Width:

|

80 cm |

|

Height:

|

170 cm |

|

Weight:

|

167 cm |

|

Volumes:

|

38 l |

|

Flow rate (dependent on the nut size):

|

15 up to 30 kg/h (with shell)

|

| Motor: | 230V |

Nut cracker Junior

The robust nut cracking machine for up to 100 kg cracked nuts with shells per hour.

The Nut cracker Junior is very robust, reliable and powerful with a volume of 300 l. The cracking machine attains a very clean cracking result of up to 100 kg/h (nuts and shells).

The Nut cracker Junior is constructed in such a way that it continuously breaks 3 nuts at a time. These should be washed first, dried, and sorted according to size. In addition, the cracker has an anti-stone system, which prevents possible damage to the cracking machine. This means that no supervision is necessary during the cracking process. For additional shell removal, the Nut cracker Junior can be combined with the Blower 400 or 800.

Details on the Nut cracker Junior

Benefits

- Flow rate can be increased up to 50 % with optional variable speed drive

- Works without supervision

- 3-phase motor 380V

- Stone safety device

- Cracking without calibration

- Optional: more performance with speed variator

- Can optionally be combined with blower type 400 or 800 for shell removal

Technical data

|

Length:

|

152 cm |

|

Width:

|

80 cm |

|

Height:

|

170 cm |

|

Weight:

|

212 Kg |

|

Volumes:

|

300 l |

|

Flow rate (dependent on the nut size):

|

70 up to 100 kg/h (with shell)

|

| Motor: | 380V |

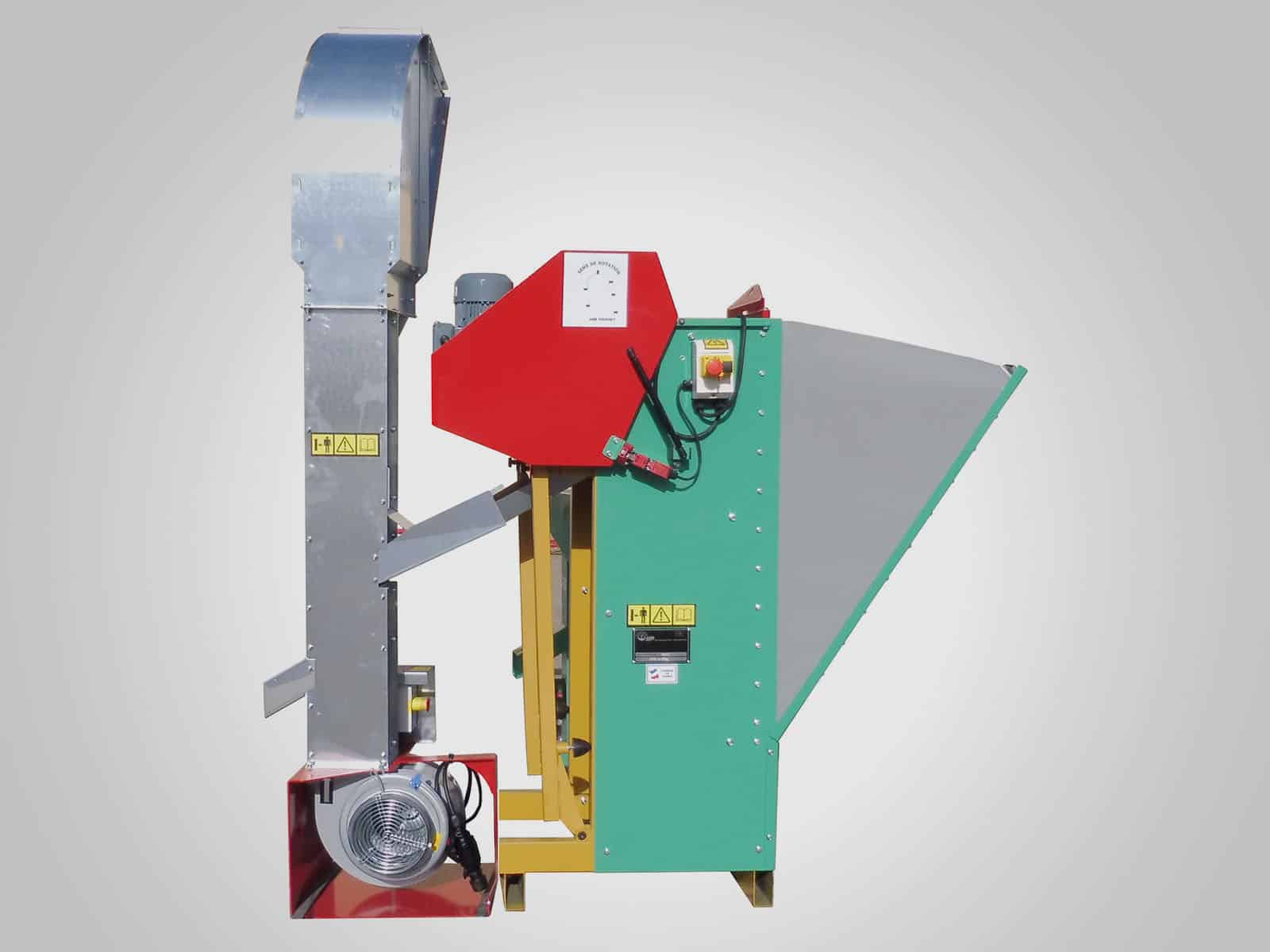

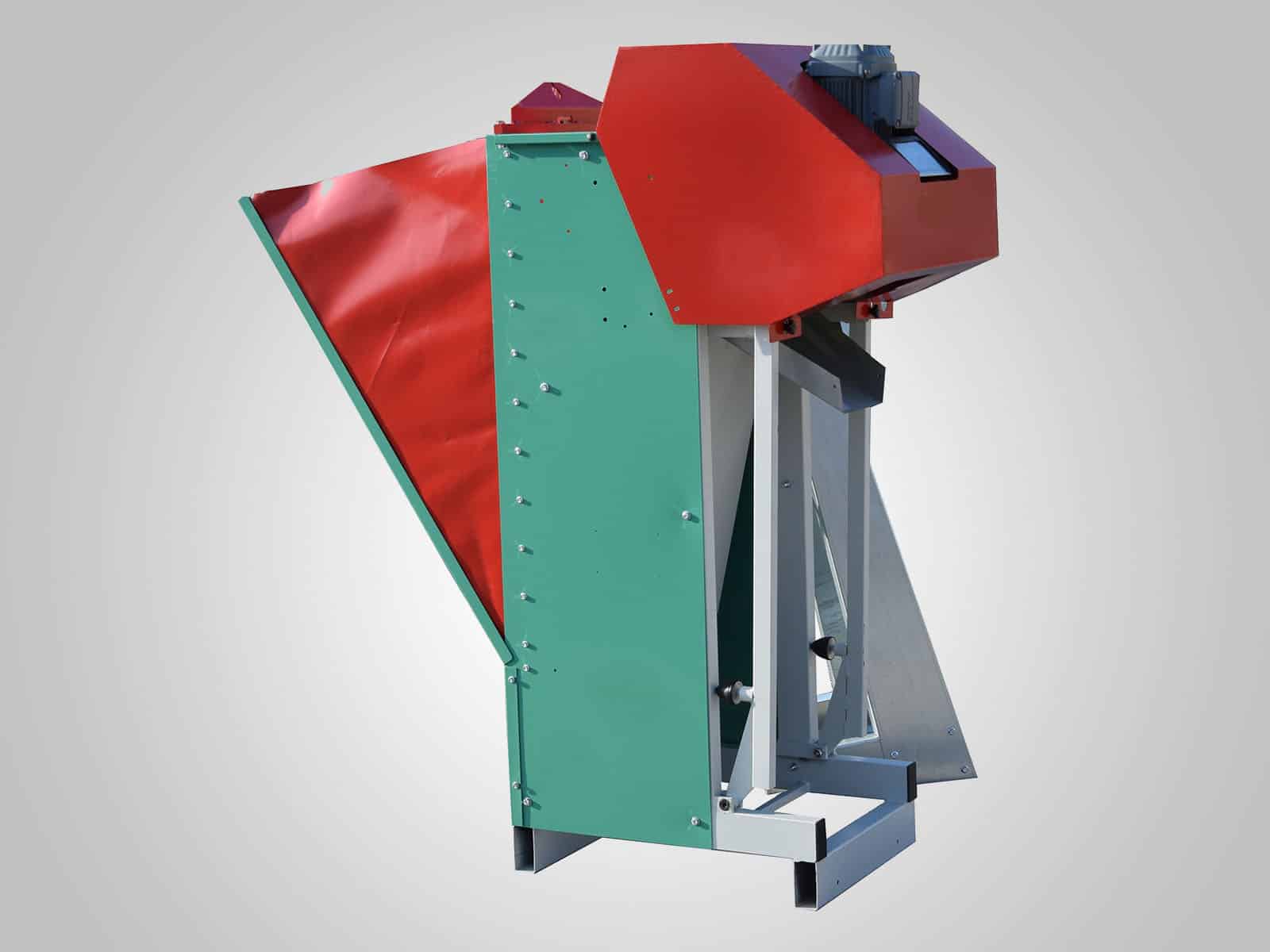

Walnut post-cracking machine

For an optimal cracking result without rework.

The walnut post-cracking machine is installed after the nut cracker in the nut processing line. With clean pre-calibration from 3 sizes (29 / 30 / 32 / 34 etc.) during cracking, up to 30 – 60 % half walnuts can be obtained. The post-cracking machine can process 40 to 120 kg nuts per hour.

With an optional calibration kit at the machine infeed, the flow rate can be increased by up to 200 kg/h. The nuts are inserted from above, re-cracked and the broken shells separated by an adjustable blower. The cracking system can be adjusted to different sizes. The sturdy frame and the robust components allow continuous operation of the post-cracking machine.

Details on the walnut post-cracking machine

Benefits

- very robust due to screwed frame

- versatile due to adjustable speed and air blower

- adjustable according to the size of the nuts

- up to 30-60% half walnuts

- post-processing up to 200 kg/h

Technical data

Mechanical system with adjustable speed & blower:

|

Length:

|

100 cm |

|

Width:

|

100 cm |

|

Height:

|

230 cm bis 283 cm |

|

Weight:

|

340 kg |

|

Flow rate:

|

40 to 120 kg/h (dependent on the nut size)

|

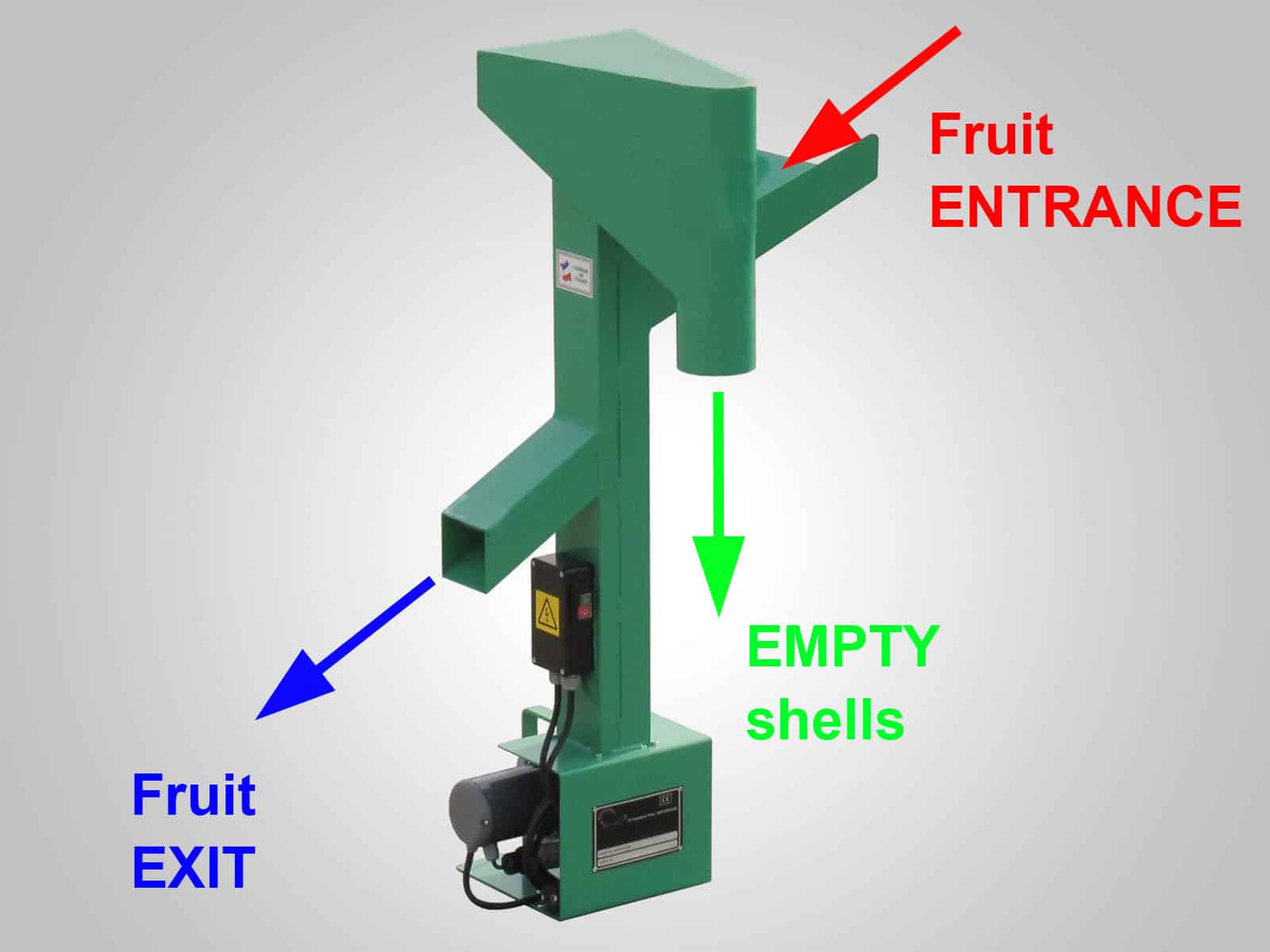

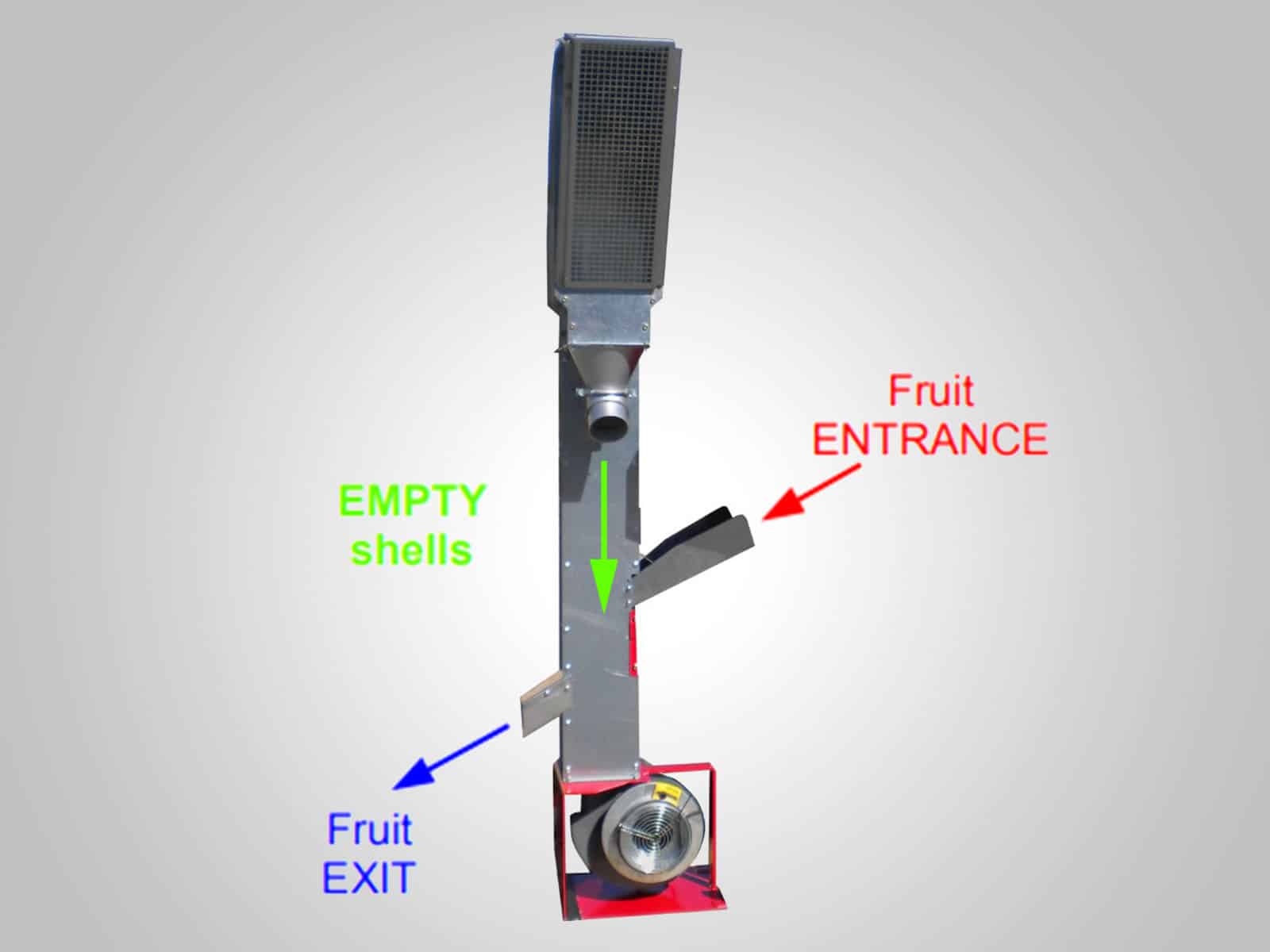

Walnut shell remover: Blower 400

The small, light shell remover for separating cores and shells.

The Blower 400 is normally installed after the Walnut Crackers Micro or Junior in the nut processing line. Using an adjustable air stream, the blower separates the broken shells from the precious nut cores after cracking.

The blower can also be used to separate empty nuts from full ones or to remove raw shells after the calibration. The Blower 400 is small and very light and allowing it to be transported easily. Up to 70 kg/h nuts can be processed using this shell remover.

Details on the walnut shell remover Blower 400

Benefits

- very quiet (62 db/a)

- robust and stably welded steel housing

- adjustable air blower through a screen

- usable in many ways

Technical data

|

Length:

|

47 cm |

|

Width:

|

54 cm |

|

Height:

|

113 cm |

|

Weight:

|

23 kg |

|

Motor:

|

220 V in direct drive with the turbine

|

|

Flow:

|

50 up to 70 kg/h

|

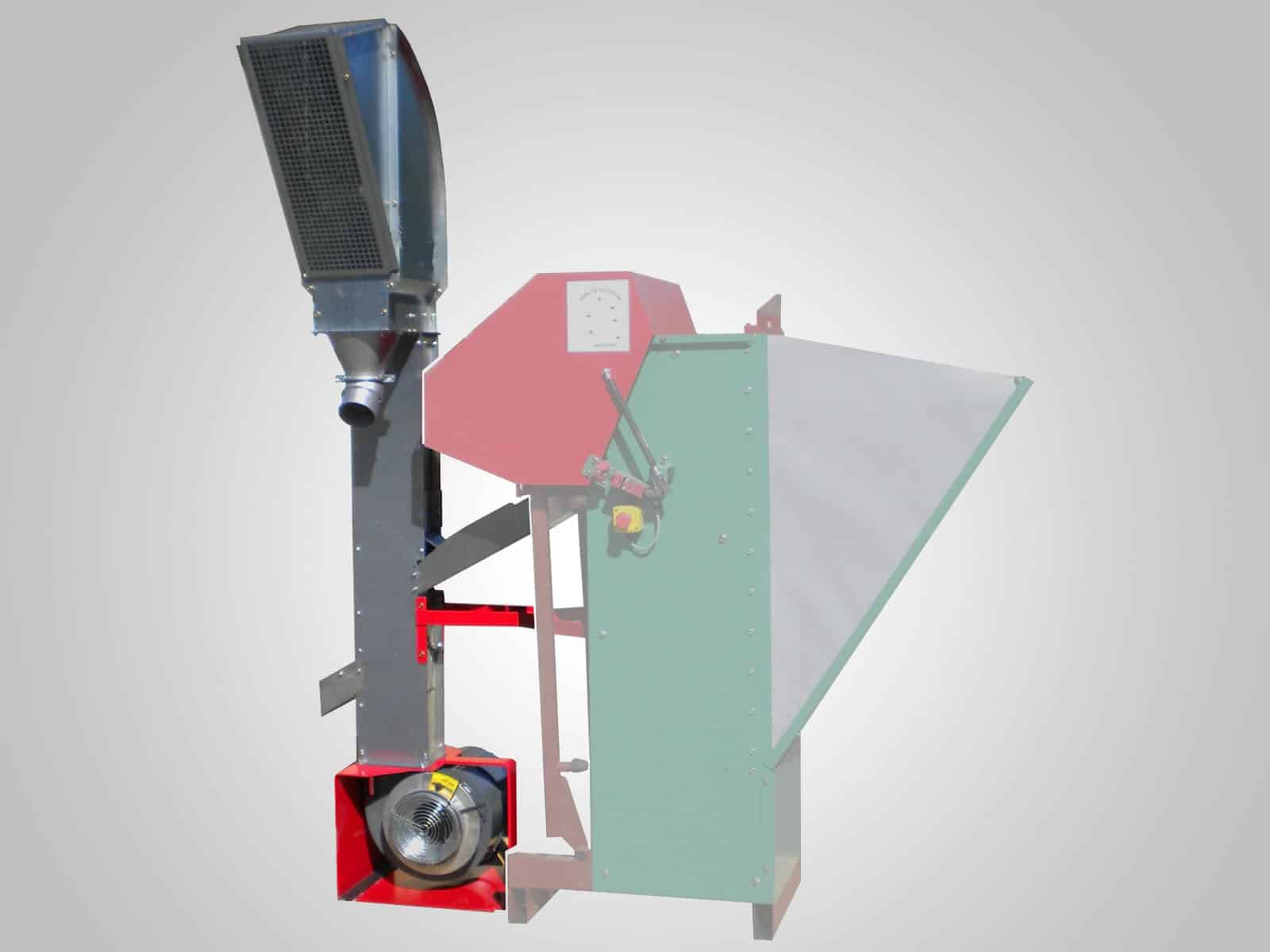

Walnut shell remover: Blower 800

Separate up to 200 kg nuts per hour.

The Blower 800 is the larger of our two walnut shell removers. The blower is preferably used after cracking with the Nut cracker Junior, to separate the nut cores and cracked shells. The Blower 800, however, is versatile.

This enables the blower to separate empty from full nuts and remove raw shells after calibration. The walnut shell remover is equipped with a powerful 3-phase 380V electric motor. The Blower 800 is used in the nut production line with the Nut cracker Junior for 70 – 100 kg/h.

Details on the walnut shell remover Blower 800

Benefits

- works quietly (62 db/a)

- usable in many ways

- adjustable blower with screen

- very stable thanks to welded steel housing

Technical data

|

Length:

|

87 cm |

|

Width:

|

64 cm |

|

Height:

|

236 cm |

|

Weight:

|

80 kg |

| Motor: |

380 V in direct drive with the turbine

|

|

Flow:

|

50 up to 200 kg/h

|

Vibration sieve for walnut halves

Sort nut halves into various sizes quickly and simply.

The vibration sieve can be used to sort according to 4 core sizes: Break, 1/4 core, 1/2 core and whole core. The sieve process is continual and dust-free. The electrical performance of the vibration sieve amounts to 0.34 kW.

The vibration sieve has a large calibration surface of 25 cm x 55 cm. The vibration sieve is multi-functional, e.g. in industrial processing or agriculture.

Details on the vibration sieve for walnut halves

Benefits

- continual sieve process

- powerful electrical drive

- large calibration size (25 cm x 55 cm)

- usable in industry and in agriculture

- various calibration sizes possible

Technical data

|

Length:

|

170 cm |

|

Width:

|

68 cm |

|

Weight:

|

220 kg |

|

Height:

|

74 cm |

|

Flow rate:

|

70 up to 100 kg/h (with shell)

|

|

Voltage:

|

380 V |

| Optionen: | verschiedene Siebgrößen möglich |